Iran Winch engineering company

was established in 1974 with the aim of supplying equipment for oil, gas and petrochemical projects. Since 1995, with the approach of domestic production and creating national production in the field of industry, it has started to manufacture steel equipment and electrical parts of petrochemicals, Oil, gas, refiners as well as steel industry. In addition, to supplying equipment to its parents Company ( Tehran Javan Co. ), it was also participated in projects in the mentioned fields in phases 8, 6-7 of South Pars, DARKHOEIN, also had cooperation with foreign contractors such as DAELIM, Toyo-GGC and Eni. It has also completed.

Several projects with domestic contractors and employers,including SAZEH, TEHRAN JONOOB, MAPNA, CHAGALESH, DORRIZ, NIOEC, NISOC and etc.

The factory of this company

is located in Mohammadshahr, Karaj, on a land with an area of 20,000 square meters and has two production workshops of 600 and 400 square meters, office space with an area of about 200 square meters, roofed warehouse with 100 square meters and open warehouse with 2000 square meters, including many equipment such as CNC punching machine, NC / BREAK press machine, cutting machine and all kinds of impact presses and other various equipment. The company has a separate warehouse at the beginning of Saveh Road with an area of 1200 square meters and 400 meters of covered warehouse to support and maintain raw materials and equipment required for projects.

Iran Winch company successfully received ISO 9001: 2000 with the helps of its experienced and committed experts and personnel in 2011 and also ISO 9001: 2015 with ISO /TS 290001: 2010 approach in 2020, environmental management system and Professional health safety based on ISO 140001, ISO 450001 with HSE-MS approach in the field of manufacturing, supplying and working as a contractor in the fields of oil, gas and petrochemicals.

For the correct implementation of a project, from a technical and construction point of view, details must be addressed. By using optimal methods and processes, continuous improvement in technical structures and industrial standards can play a key role in improving projects and improving final quality. “Professional training, using new technologies, and creating a collaborative work culture are also measures that can help improve the overall work process and achieve the set goals.

We use this as the main objective in the provision of services and we are proud to offer it as a powerful tool to improve the quality and implementation of technical projects in the service provision.

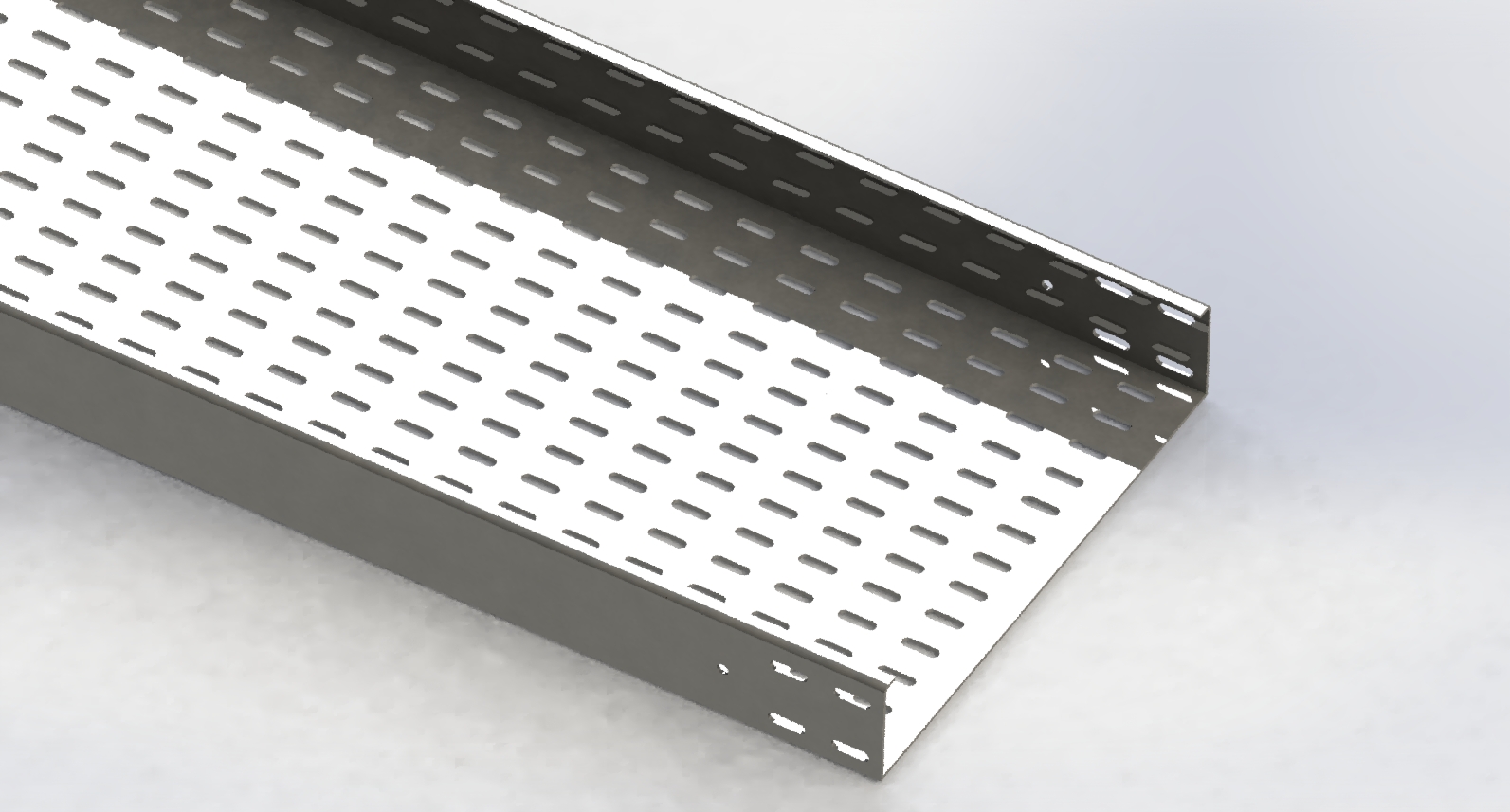

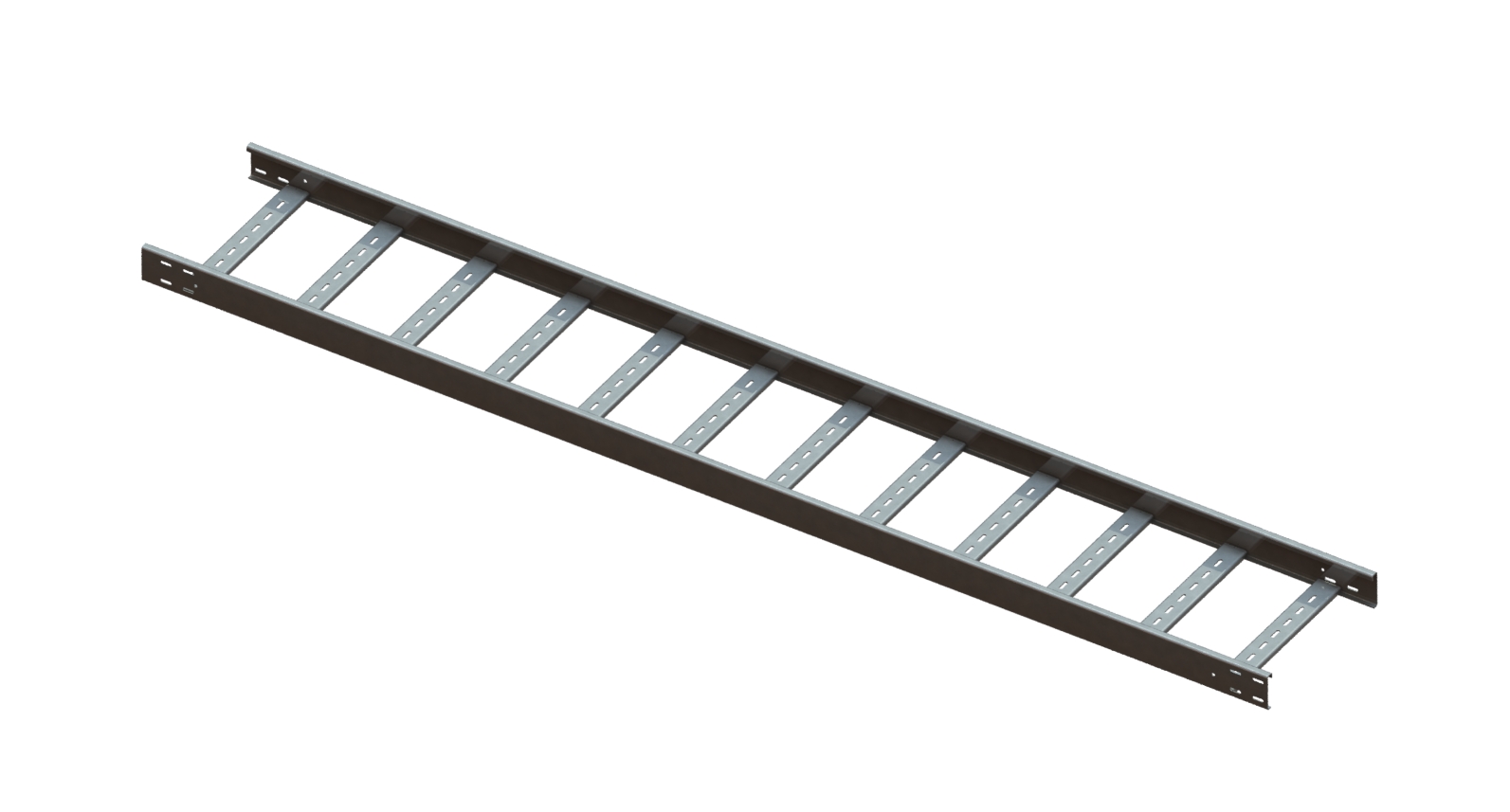

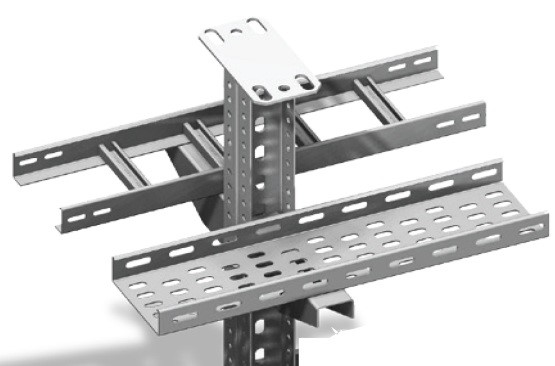

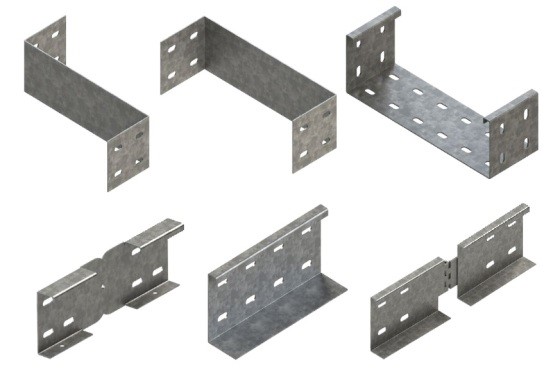

PRODUCT

Browse through our range of multi-discipline support systems, cable ladders, cable trays and accessories.

Customers

.